Could this new design revolutionise Australian sheep shearing?

It’s time for our big reveal: the innovative engineers at 4c Design, the same team that invented the Numnuts device, have turned their minds to a smart shearing handpiece that may be the future look of shearing in Australia. The reason for our interest is simple: as well as being Mr Numnuts, Robin Smith is also founder of 4c Design, a design engineering innovation company that has taken a special interest in sheep projects in recent years.

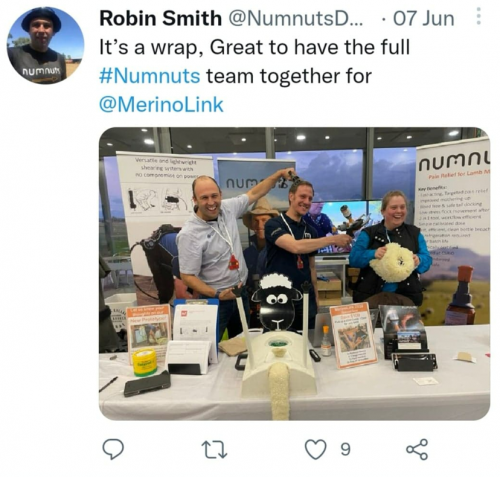

Recent demo at MerinoLink

Indeed, eagle-eyed Twitter followers may have noticed the display stand in the background of our recent photo from MerinoLink near Wagga Wagga. Not only that, but in the foreground, Robin is clearly giving Dougal Deans a new haircut with the device! It’s safe to say that the Senesino team, Robin, Dougal and Sarah spent nearly as much of their time on the Numnuts stand discussing smart shearing as ‘numnutting’!

Producers at MerinoLink were also treated to a demo when Justin Jones used the prototype to shear a couple of crossbred lambs. This event was covered by journalist Stephen Jones in his write up for The Rural: Mobile shearing hand piece to revolutionise the industry.

What is a smart shearing device?

The 4c Design innovators are developing a simple portable system that paves the way for semi-automated shearing. With an electronic motor and smaller handpiece, the device combines portability with the capacity to log data through in-built sensors.

The data gathered helps the engineers to measure and adjust the torque and power to optimise battery life. Setting the handpiece cutter tension is currently something that is done by ‘feel and noise’. It takes experience, so can be a difficult skill for apprentices to develop quickly. Having smart motor feedback paves the way for improvements in this area.

Shearers also have increased freedom as to how and where they work, whether that’s in the shed, the paddock, or cradles in the yards. Rather than being pinned to a downtube, they can explore new cutting patterns. The shearer can use a hand shearing pattern, whereby they move around the sheep, rather than manhandling the animal.

This is a valuable development, as moving heavy sheep is major cause of injury. The designers aim to reduce the physical toll that the work takes on shearers themselves. The system with its flexi drive would be ideal for platform upright shearing, while potentially paving the way for production line shearing (think Henry T Ford).

Prototype support from Australian Wool Innovation

The demo was organised by Australian Wool Innovation (AWI), which has been involved in the development of the device. Dr Jane Littlejohn, General Manager of Research, and Dr Carolina Diaz, AWI Program Manager Agri-tech, were both present at MerinoLink.

“We are trying to introduce efficiencies into the wool removal and wool harvesting process. The long-term aim is to have options for growers for wool harvesting beyond the traditional shearing,” Dr Littlejohn explained in The Rural.

“It is also a process to give society and consumers confidence in the welfare of our sheep, and at the same time looking after the health and welfare of the shearers.”

Next steps in the development process

While AWI is an interested party in the development of this prototype, future investment is needed for the research arm of the R&D process. Numnuts was 10 years in development, largely because 4c Design undertook extensive research, prototyping and engineering to ensure effectiveness of the device and medication, to validate an improvement in animal welfare. This was required to meet regulatory requirements, but it also reflects the ethos of an ethical innovative company.

The last word goes to Robin Smith, who seems unable to stop seeing areas where sheep producing processes and animal welfare can be improved through technological innovation.

“After 3yrs of getting Numnuts going in Australia, it’s been great to get back to the tools (so to speak) with the development of this prototype shearing system. It’s pretty nerve-wracking – development testing of new prototype systems like the smart shearing concept isn’t normally done in front of a live audience like the 100 or so that viewed the prototype unit at MerinoLink!

“Yet we felt the project was at an important juncture. If the industry feels there isn’t a place for this sort of concept, we can leave it here… that’s fine, as it’s the nature of R&D. However, if they decide that there is some merit in the concept, they can get behind it.”

“As a single product (Numnuts®) company, we are entirely reliant on our pain relief sales to be able to fund (or match fund) development of new shearing equipment. With that awareness, the best thing the industry can do to move the shearing innovation forward, is for farmers to use Numnuts® at lamb marking!!”